A1SS91

- Brand: MITSUBISHI

- Country: JAPAN

- Name: I/O bus monitoring module

- Model: A1SS91

- Price: 0 >

MITSUBISHI A1SS91

Length: 65CM.

Function: connect GM-FX.

Corresponding models: FX2N-10GM, FX2N-20GM. Type: HC-PQ type.

Output power: 0.1kw.

Rated speed: 3000r/min.

Electromagnetic brake: there.

Key axis: D type shaft.

Motor aspects: the material, structure and processing technology of the servo motor is much higher than that of AC motor,

That is when the driver output current, voltage, frequency change is fast power supply,

The servo motor can change according to the change of the response of the power supply,

Response characteristics and anti overload capacity is much higher than the AC motor drive,

Motor aspects of the serious differences between the two are fundamentally different performance A1SS91

That is not the inverter output can not change so fast power signal,

But the motor itself can not react,

So in the frequency of the internal algorithm set to protect the motor to do the corresponding overload A1SS91.

Of course, even without the ability to set the output of the inverter is limited,

Some of the excellent performance of the inverter can be directly driven servo motor. Enter 8 points: 24VDC A1SS91.

4 wire type .

Response time: 1.5ms.

Output 8 points: 24VDC.

Transistor output.

Waterproof connector type.

MITSUBISHI PLC hardware implementation

Hardware implementation is mainly for the control cabinet and other hardware design and field construction.

Design control cabinet and the operating table and other parts of the electrical wiring diagram and wiring diagram.

Electrical interconnection diagram of each part of the design system.

According to the construction drawings of the site wiring, and carry out a detailed inspection.

Because the program design and hardware implementation can be carried out at the same time,

So the design cycle of the MITSUBISHI PLC control system can be greatly reduced.

MITSUBISHI PLC online debugging.

On-line debugging is the process that will through the siimulation debugging to furtherr carry on the on-line unification to adjust A1SS91.

On-line debugging process should be step by step,

From MITSUBISHI PLC only connected to the input device, and then connect the output device, and then connect to the actual load and so on and so on stepp bby step A1SS91.

If you do not meet the requirements, the hardware and procedures for adjustment.

Usually only need to modify the part of the program can be.

A1SS91 Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=A1SS91&select=5

Function: connect GM-FX.

Corresponding models: FX2N-10GM, FX2N-20GM. Type: HC-PQ type.

Output power: 0.1kw.

Rated speed: 3000r/min.

Electromagnetic brake: there.

Key axis: D type shaft.

Motor aspects: the material, structure and processing technology of the servo motor is much higher than that of AC motor,

That is when the driver output current, voltage, frequency change is fast power supply,

The servo motor can change according to the change of the response of the power supply,

Response characteristics and anti overload capacity is much higher than the AC motor drive,

Motor aspects of the serious differences between the two are fundamentally different performance A1SS91

That is not the inverter output can not change so fast power signal,

But the motor itself can not react,

So in the frequency of the internal algorithm set to protect the motor to do the corresponding overload A1SS91.

Of course, even without the ability to set the output of the inverter is limited,

Some of the excellent performance of the inverter can be directly driven servo motor. Enter 8 points: 24VDC A1SS91.

4 wire type .

Response time: 1.5ms.

Output 8 points: 24VDC.

Transistor output.

Waterproof connector type.

MITSUBISHI PLC hardware implementation

Hardware implementation is mainly for the control cabinet and other hardware design and field construction.

Design control cabinet and the operating table and other parts of the electrical wiring diagram and wiring diagram.

Electrical interconnection diagram of each part of the design system.

According to the construction drawings of the site wiring, and carry out a detailed inspection.

Because the program design and hardware implementation can be carried out at the same time,

So the design cycle of the MITSUBISHI PLC control system can be greatly reduced.

MITSUBISHI PLC online debugging.

On-line debugging is the process that will through the siimulation debugging to furtherr carry on the on-line unification to adjust A1SS91.

On-line debugging process should be step by step,

From MITSUBISHI PLC only connected to the input device, and then connect the output device, and then connect to the actual load and so on and so on stepp bby step A1SS91.

If you do not meet the requirements, the hardware and procedures for adjustment.

Usually only need to modify the part of the program can be.

A1SS91 Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=A1SS91&select=5

...more relevant model market price >>>>

Related products

MITSUBISHI

Input module

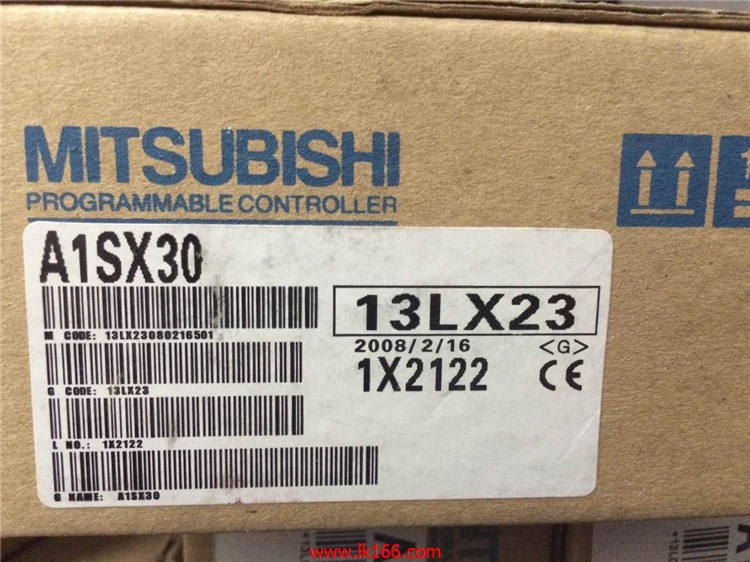

A1SX30

Input type: AC/DC.

Input points: 16 poin

MITSUBISHI

Profibus interface module

A1SJ71PB96F

Availale network: Profius-FMS.

Functio

MITSUBISHI

Power module

A1S62P

Input: AC100 120V/200 240V,

Output:

MITSUBISHI

DC source type input module

A1SX71

Type of input: DC source.

Input points: