MR-JE-200A

- Brand: MITSUBISHI

- Country: JAPAN

- Name: amplifier

- Model: MR-JE-200A

- Price: U.S.$ 2125.42

MITSUBISHI MR-JE-200A

MITSUBISHI inverter FR-L740 series.

Voltage level: three phase 400V.

Frequency converter capacity: 18.5KW.

Integration of the three works the core technology, the outstanding performance of reeling, release the high cost of bright light.

Wide range of professional use and advanced control.

Professional built-in function to ensure the constant material tension, suitable for the application of printing and packaging industry MR-JE-200A

Fusion application of the tension products of MITSUBISHI by inverter.

Suitable for tension control of high precision cable and material processing occasions.

Professional function to ensure the safe operation of textile machinery equipment,

The spinning quality and production efficiency are improved MR-JE-200A. The application of textile machinery and equipment. Power: 55kw.

Purpose: to suppress the power harmonics.

Connected to the inverter input, can be used to improve the power factor, reduce the input side of the high harmonic current.

According to the motor power used to select AC reactor.

(when the inverter capacity is greater than the motor capacity, is still based on the motor capacity to choose MR-JE-200A. ) Enter 16 points: 24VDC.

Response time 1.5ms.

Waterproof type.

4 wire type.

Waterproof connector type.

MITSUBISHI PLC hardware implementation

Hardware implementation is mainly for the control cabinet and other hardware design and field construction.

Design control cabinet and the operating table and other parts of the electrical wiring diagram and wiring diagram.

Electrical interconnection diagram of each part of the design system.

According to the construction drawings of the site wiring, and carry out a detailed inspection.

Because the program design and hardware implementation can be carried out at the same time,

So the design cycle of the MITSUBISHI PLC control system can be greatly reduced.

MITSUBISHI PLC online debugging.

On-line debugging is the process that will through the simulaation debugging to furtherr carry on the on-line unification to adjust MR-JE-200A.

On-line debugging process should be step by step,

From MITSUBISHI PLC only connected to the input device, and then connect the output device, and then connect to the actual load and so on and so on stepp bby step MR-JE-200A.

If you do not meet the requirements, the hardware and procedures for adjustment.

Usually only need to modify the part of the program can be.

MR-JE-200A Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=MR-JE-200A&select=5

Voltage level: three phase 400V.

Frequency converter capacity: 18.5KW.

Integration of the three works the core technology, the outstanding performance of reeling, release the high cost of bright light.

Wide range of professional use and advanced control.

Professional built-in function to ensure the constant material tension, suitable for the application of printing and packaging industry MR-JE-200A

Fusion application of the tension products of MITSUBISHI by inverter.

Suitable for tension control of high precision cable and material processing occasions.

Professional function to ensure the safe operation of textile machinery equipment,

The spinning quality and production efficiency are improved MR-JE-200A. The application of textile machinery and equipment. Power: 55kw.

Purpose: to suppress the power harmonics.

Connected to the inverter input, can be used to improve the power factor, reduce the input side of the high harmonic current.

According to the motor power used to select AC reactor.

(when the inverter capacity is greater than the motor capacity, is still based on the motor capacity to choose MR-JE-200A. ) Enter 16 points: 24VDC.

Response time 1.5ms.

Waterproof type.

4 wire type.

Waterproof connector type.

MITSUBISHI PLC hardware implementation

Hardware implementation is mainly for the control cabinet and other hardware design and field construction.

Design control cabinet and the operating table and other parts of the electrical wiring diagram and wiring diagram.

Electrical interconnection diagram of each part of the design system.

According to the construction drawings of the site wiring, and carry out a detailed inspection.

Because the program design and hardware implementation can be carried out at the same time,

So the design cycle of the MITSUBISHI PLC control system can be greatly reduced.

MITSUBISHI PLC online debugging.

On-line debugging is the process that will through the simulaation debugging to furtherr carry on the on-line unification to adjust MR-JE-200A.

On-line debugging process should be step by step,

From MITSUBISHI PLC only connected to the input device, and then connect the output device, and then connect to the actual load and so on and so on stepp bby step MR-JE-200A.

If you do not meet the requirements, the hardware and procedures for adjustment.

Usually only need to modify the part of the program can be.

MR-JE-200A Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=MR-JE-200A&select=5

...more relevant model market price >>>>

Related products

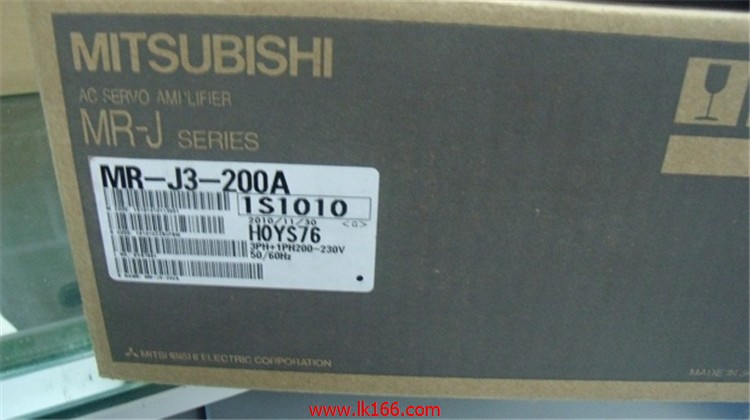

MITSUBISHI

Universal pulse interface driver

MR-J3-200A

MITSUBISHI motor universal AC servo ampl

MITSUBISHI

amplifier

MR-JE-10A

MITSUBISHI universal AC servo amplifier

MITSUBISHI

Servo driver

MR-J4-200A4

1 axis servo amplifier.

MITSUBISHI gener

MITSUBISHI

General motors for MR-JE and MR-E

HF-SN52J-S100

Type: HF-SN servo motor, medium inertia