FR-A5NC

- Brand: MITSUBISHI

- Country: JAPAN

- Name: Install a compatible option

- Model: FR-A5NC

- Price: U.S.$ 318.64

MITSUBISHI FR-A5NC

Power: 11kw.

Voltage: 400V.

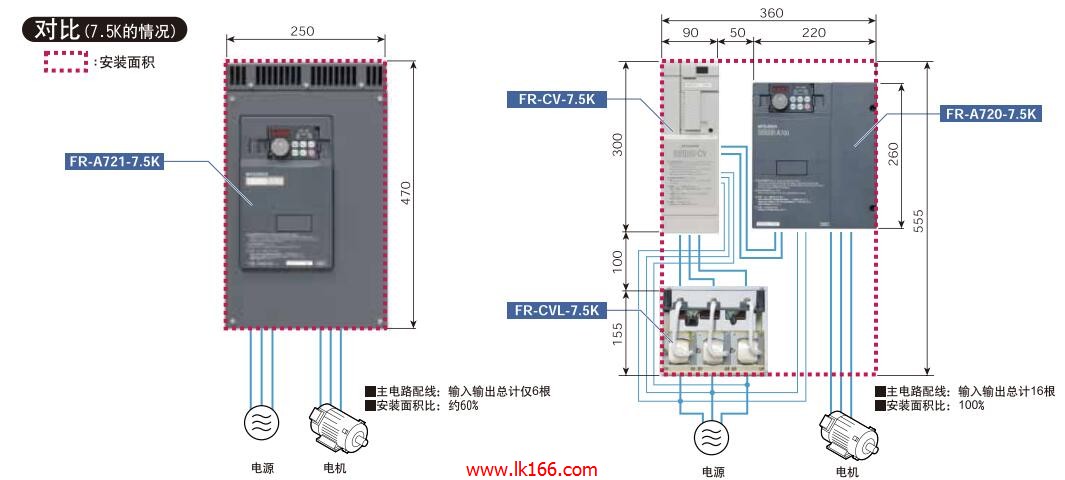

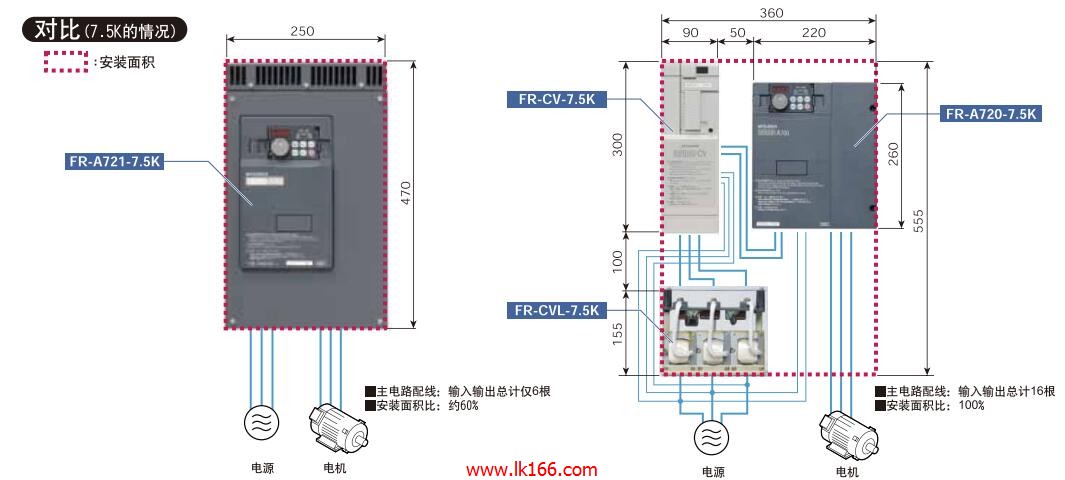

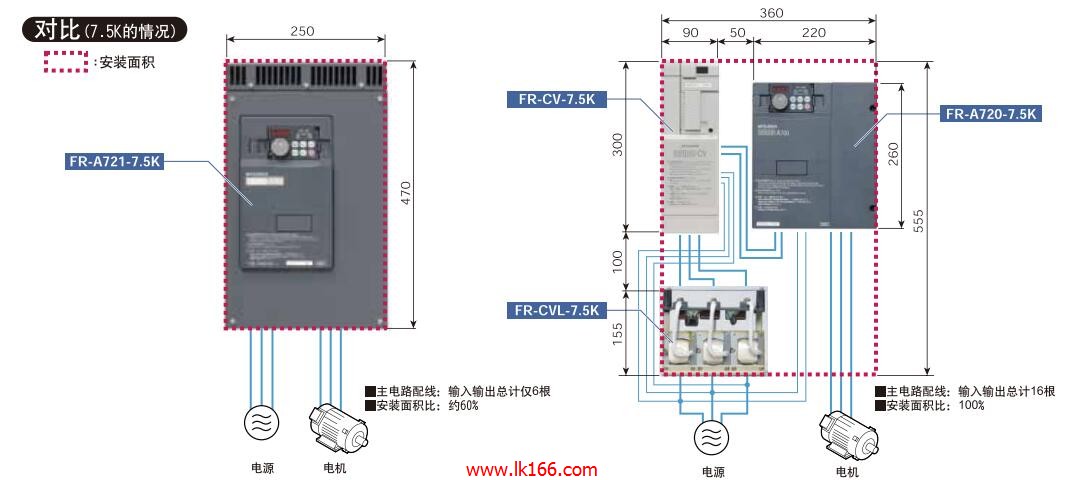

There are 100% braking torque output in continuous regeneration, which can correspond to the continuous regeneration operation of the pipeline control.

There is no need to install the braking unit for each frequency converter, which can reduce the comprehensive space and reduce the comprehensive cost .

Renewable energy can be used for other frequency converter, excess energy back to the grid, to achieve energy saving FR-A5NC For MR-J2S-700A (4) /CP/CL or less.

Encoder adapter for HC-SFS; HC-LFS; HC-RFS; 2000r/min HA-LFS; HC-UFS servo motor. Length: 5 meters.

Operation panel or parameter unit connection line. Servo motor series: ultra low inertia, low power FR-A5NC.

Rated output: 0 . 2kw.

Rated speed: 3000r/min.

Electromagnetic brake: with.

Shaft end specification: Standard (straight axis).

Features: ultra low inertia is very suitable for high frequency operation.

IP level: IP65.

Application example:

1, insert machine.

2, assembly machinery.

Rotary servo motor.

Numerous motor series and wide motor power range can be used to meet different applications FR-A5NC.

The protection level of the HF-KP/HF-MP/HC-LP/HC-RP/HC-UP servo motor to improve the environmental safety is IP65 (except the shaft part) . Motor series: medium inertia, medium power.

Rated output power: 0.85kw.

Rated speed: 1000r/min.

Whether to take the brake: No.

Shaft end: Standard (straight).

Protection level: IP65 (IP67).

Features: medium inertia from low speed to high speed three modes for selection, suitable for different applications.

Application examples: transmission machinery, robots, X-Y working platform.

High resolution encoder 131072p/rev (17 bit).

The encoder with high resolution ensures excellent performance and stability at low speed.

All motor dimensions are the same as before and all are compatible with the wiring. Type of input: DC source.

Input points: 32 points.

Input voltage: DC24.

Input current: 7mA.

Connection mode: terminal row.

Common common point: 32.

Sequential function flow chart language is designed to satisfy the sequential logic control.

The process of sequential process action is divided into steps and transformation conditions,

According to the transfer condition, the control system is distributed in the function flow sequence,

Step by step according to the sequence of actions.

Each step represents a control function, represented by the box.

In the box, the ladder logic is used to complete the task of the corresponding control function.

This programming language makes the program structure clear and easy to read and maintain,

Greatly reduce the programming workload, shorten the programming and debugging time.

Used in the system of the size of the school, procedures for more complex occasions.

Sequence function flow chart programming language features: to function as the main line, in accordance with thee functional flow of the order of distribution, clear, easy to understand the user program,

Avoid the defect of ladder diagram or other languages,

At the same time, the use of ladder language to avoid the use of ladder programming,

Due to the compllicaated mechanical interlock, the structure of the user program is complex and difficult to understand,

User program scan time is also greatly reduced FR-A5NC FR-A5NC.

FR-A5NC Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=FR-A5NC&select=5

Voltage: 400V.

There are 100% braking torque output in continuous regeneration, which can correspond to the continuous regeneration operation of the pipeline control.

There is no need to install the braking unit for each frequency converter, which can reduce the comprehensive space and reduce the comprehensive cost .

Renewable energy can be used for other frequency converter, excess energy back to the grid, to achieve energy saving FR-A5NC For MR-J2S-700A (4) /CP/CL or less.

Encoder adapter for HC-SFS; HC-LFS; HC-RFS; 2000r/min HA-LFS; HC-UFS servo motor. Length: 5 meters.

Operation panel or parameter unit connection line. Servo motor series: ultra low inertia, low power FR-A5NC.

Rated output: 0 . 2kw.

Rated speed: 3000r/min.

Electromagnetic brake: with.

Shaft end specification: Standard (straight axis).

Features: ultra low inertia is very suitable for high frequency operation.

IP level: IP65.

Application example:

1, insert machine.

2, assembly machinery.

Rotary servo motor.

Numerous motor series and wide motor power range can be used to meet different applications FR-A5NC.

The protection level of the HF-KP/HF-MP/HC-LP/HC-RP/HC-UP servo motor to improve the environmental safety is IP65 (except the shaft part) . Motor series: medium inertia, medium power.

Rated output power: 0.85kw.

Rated speed: 1000r/min.

Whether to take the brake: No.

Shaft end: Standard (straight).

Protection level: IP65 (IP67).

Features: medium inertia from low speed to high speed three modes for selection, suitable for different applications.

Application examples: transmission machinery, robots, X-Y working platform.

High resolution encoder 131072p/rev (17 bit).

The encoder with high resolution ensures excellent performance and stability at low speed.

All motor dimensions are the same as before and all are compatible with the wiring. Type of input: DC source.

Input points: 32 points.

Input voltage: DC24.

Input current: 7mA.

Connection mode: terminal row.

Common common point: 32.

Sequential function flow chart language is designed to satisfy the sequential logic control.

The process of sequential process action is divided into steps and transformation conditions,

According to the transfer condition, the control system is distributed in the function flow sequence,

Step by step according to the sequence of actions.

Each step represents a control function, represented by the box.

In the box, the ladder logic is used to complete the task of the corresponding control function.

This programming language makes the program structure clear and easy to read and maintain,

Greatly reduce the programming workload, shorten the programming and debugging time.

Used in the system of the size of the school, procedures for more complex occasions.

Sequence function flow chart programming language features: to function as the main line, in accordance with thee functional flow of the order of distribution, clear, easy to understand the user program,

Avoid the defect of ladder diagram or other languages,

At the same time, the use of ladder language to avoid the use of ladder programming,

Due to the compllicaated mechanical interlock, the structure of the user program is complex and difficult to understand,

User program scan time is also greatly reduced FR-A5NC FR-A5NC.

FR-A5NC Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=FR-A5NC&select=5

...more relevant model market price >>>>

Related products

MITSUBISHI

AC reactor

FR-HAL-H75K

Power: 75kw.

Purpose: to suppress the po

MITSUBISHI

Directional control /PLG module

FR-A8AP

Can use the encoder to perform vector co

MITSUBISHI

Rectifying partial off type frequency converter

FR-A842-12120-2-60

MITSUBISHI inverter series: FR-A800.

Vol

MITSUBISHI

Three phase 400V grade frequency converter

FR-A840-00126-2-60

MITSUBISHI inverter series: FR-A800.

Vol