A68RD3N

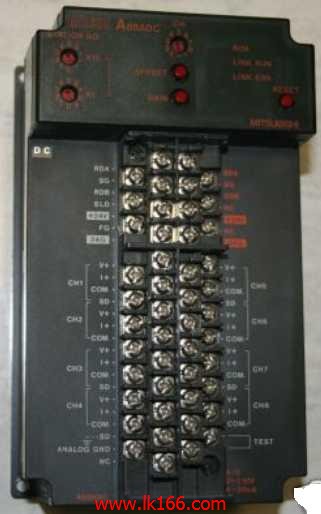

- Brand: MITSUBISHI

- Country: JAPAN

- Name: Temperature input module

- Model: A68RD3N

- Price: U.S.$ 1920.34

MITSUBISHI A68RD3N

Max input / output points: 16 points.

Power supply voltage: 24VDC.

Input points: 8 points.

Output points: 8 points.

Output type: relay.

Power consumption: 6W.

Weight (kg):0.25.

Size (WxHxD) mm:35x90x89.

Taking into account space saving and processing speed.

Connector input and output type compact high performance universal machine .

Compact, scalable input / output A68RD3N.

Can connect analog quantity, communication, positioning, etc A68RD3N.

Rich special extension equipment for FX2N.

By connecting the compact FX2rvc series with the input and output expansion module.

The input and output can be extended to 256 points.

Built in 8000 step RAM memory.

By installing the memory card box, the maximum can be extended to the 16000 step A68RD3N.

Overseas oriented products meet all kinds of international standards.

Use terminal module to replace connector connection or relay terminal row connection,

So as to save the wiring inside the cabinet. Motor series: low inertia, medium capacity.

Using a serial absolute / incremental encoder.

Rated output power: 5.0kw.

Rated speed: 3000rpm.

With the brake: without A68RD3N.

Shaft end: straight shaft .

Performance comparison of servo motor and stepping motor.

Stepper motor as an open-loop control system, and modern digital control technology has the essential link.

In the current domestic digital control system, stepping motor is widely used.

With the emergence of digital AC servo system, AC servo motor is more and more used in digital control system.

In order to adapt to the development trend of digital control, most of the motion control system adopts stepping motor or full digital AC servo motor as executive motor.

Although they are similar in control mode (pulse train and directional signal), there are great differences in performance and application.

The use performance of the two are compared. Input points: 16 points.

Input voltage and current: 3/7mA DC12/24V.

Input response time: 10ms.

16 point /1 a public side.

Positive and negative sharing.

Output points: 16 points.

Output voltage: DC24V/AC240V, 2A/1 point, 4A/ common end.

Output response time: 12ms.

Output type: relay output.

8 point /1 a public end, 4 points / a public end.

50 point terminal station.

Control solenoid valve required I/O points by the action principle of the solenoid valve can be known,

A single coil solenoid valve with PLC control to 2 input and 1 output,

A double coil solenoid valve requires 3 inputs and 2 outputs,

A button needs an input; a light sensitive switch needs 4 or 2 inputs,

A signal lamp needs 1 output, band switch,

Several bands are required for several inputs,

In general, a variety of position switches are required to take up 2 input points.

MITSUBISHI PLC is the main product in the production of MITSUBISHI motor in Dalian.

It uses a kind of programmable memory for its internal storage procedures,

Execute logic operation, sequence control, timing, counting and arithmetic operations, user oriented instruction,

And through digital or analog input / output control of various types of machinery or production process.

The number of I/O thyristor DC motor control required tube DC motor speed control system is the main form of DC speed regulation,

The thyristor rectifier unit is used to supply power to the DC motor.

PLC control of the DC drive system, the input of the PLC in addition to the main signal outside the signal,

We need to consider the switcching signal, the fault signaal transmission device, brake signal and fan fault signal A68RD3N.

The output of the PLC mainly consider the speed command signal positive 1~3 level, 1~3 level, allowing reverse switching signal and brake open signal etc..

In general, a reversible DC drivee ssystem controlled by PLC is approximately 12 input points and 8 output points,

An irreversible DC drive system requires 9 inputs and 6 output points A68RD3N.

A68RD3N Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=A68RD3N&select=5

Power supply voltage: 24VDC.

Input points: 8 points.

Output points: 8 points.

Output type: relay.

Power consumption: 6W.

Weight (kg):0.25.

Size (WxHxD) mm:35x90x89.

Taking into account space saving and processing speed.

Connector input and output type compact high performance universal machine .

Compact, scalable input / output A68RD3N.

Can connect analog quantity, communication, positioning, etc A68RD3N.

Rich special extension equipment for FX2N.

By connecting the compact FX2rvc series with the input and output expansion module.

The input and output can be extended to 256 points.

Built in 8000 step RAM memory.

By installing the memory card box, the maximum can be extended to the 16000 step A68RD3N.

Overseas oriented products meet all kinds of international standards.

Use terminal module to replace connector connection or relay terminal row connection,

So as to save the wiring inside the cabinet. Motor series: low inertia, medium capacity.

Using a serial absolute / incremental encoder.

Rated output power: 5.0kw.

Rated speed: 3000rpm.

With the brake: without A68RD3N.

Shaft end: straight shaft .

Performance comparison of servo motor and stepping motor.

Stepper motor as an open-loop control system, and modern digital control technology has the essential link.

In the current domestic digital control system, stepping motor is widely used.

With the emergence of digital AC servo system, AC servo motor is more and more used in digital control system.

In order to adapt to the development trend of digital control, most of the motion control system adopts stepping motor or full digital AC servo motor as executive motor.

Although they are similar in control mode (pulse train and directional signal), there are great differences in performance and application.

The use performance of the two are compared. Input points: 16 points.

Input voltage and current: 3/7mA DC12/24V.

Input response time: 10ms.

16 point /1 a public side.

Positive and negative sharing.

Output points: 16 points.

Output voltage: DC24V/AC240V, 2A/1 point, 4A/ common end.

Output response time: 12ms.

Output type: relay output.

8 point /1 a public end, 4 points / a public end.

50 point terminal station.

Control solenoid valve required I/O points by the action principle of the solenoid valve can be known,

A single coil solenoid valve with PLC control to 2 input and 1 output,

A double coil solenoid valve requires 3 inputs and 2 outputs,

A button needs an input; a light sensitive switch needs 4 or 2 inputs,

A signal lamp needs 1 output, band switch,

Several bands are required for several inputs,

In general, a variety of position switches are required to take up 2 input points.

MITSUBISHI PLC is the main product in the production of MITSUBISHI motor in Dalian.

It uses a kind of programmable memory for its internal storage procedures,

Execute logic operation, sequence control, timing, counting and arithmetic operations, user oriented instruction,

And through digital or analog input / output control of various types of machinery or production process.

The number of I/O thyristor DC motor control required tube DC motor speed control system is the main form of DC speed regulation,

The thyristor rectifier unit is used to supply power to the DC motor.

PLC control of the DC drive system, the input of the PLC in addition to the main signal outside the signal,

We need to consider the switcching signal, the fault signaal transmission device, brake signal and fan fault signal A68RD3N.

The output of the PLC mainly consider the speed command signal positive 1~3 level, 1~3 level, allowing reverse switching signal and brake open signal etc..

In general, a reversible DC drivee ssystem controlled by PLC is approximately 12 input points and 8 output points,

An irreversible DC drive system requires 9 inputs and 6 output points A68RD3N.

A68RD3N Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=A68RD3N&select=5

...more relevant model market price >>>>

Related products

MITSUBISHI

Temperature input module

A68RD4N

8 channels.

4 wire platinum measuring an

MITSUBISHI

Temperature input module

A68RD4

8 channels.

4 wire platinum measuring an

MITSUBISHI

Analog input module

A68ADC

8 channels.

Input: DC-10 10V/DC4 20m

MITSUBISHI

Temperature input module

A68RD3

8 channels.

3 wire platinum measuring an