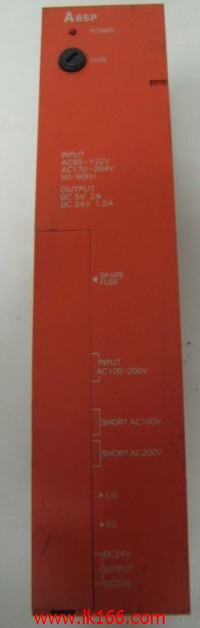

A65P

- Brand: MITSUBISHI

- Country: JAPAN

- Name: Power module

- Model: A65P

- Price: U.S.$ 891.53

MITSUBISHI A65P

Analog channel: 4 channels.

Input / output (resolution): 0 ~ 4000.

Conversion speed: 100ms/4 channel.

Analog module installation.

Power supply: AC170V ~ 264V.

According to the control requirements of the system, using the appropriate design method to design MITSUBISHI PLC program.

Procedures to meet the requirements of system control as the main line,

Write one by one to achieve the control function or the sub task of the program,

Gradually improve the functions specified by the system A65P

MITSUBISHI PLC detection, fault diagnosis and display and other procedures.

These procedures are relatively independent, generally in the basic completion of the program design and then add A65P.

Hardware simulation method is to use a number of hardware equipment to simulate the generation of the signal,

The signals are connected to the input end of the PLC system in a hard wired way, and the timeliness is strong .

Software simulation method is in the MITSUBISHI PLC in the preparation of a set of simulation program,

The simulation provides the field signal, which is simple and easy to operate, but it is not easy to guarantee the timeliness A65P.

Simulation of the process of debugging, debugging method can be used to segment, and the monitoring function of programmer. Input voltage range: AC100 ~ 120V.

Output voltage: DC24V.

Output current: 0.6A.

Relay output interface circuit of PLC

Working process: when the internal circuit output digital signal 1,

There is a current flowing through, the relay coil has a current, and then the normally open contact is closed,

Provide load current and voltage.

When the internal circuit outputs a digital signal 0, there is no current flowing through it,

The relay coil does not have a current, and the normally open contact is broken off,

A current or voltage that is disconnected from the load.

It is through the output interface circuit to the internal digital circuit into a signal to make the load action or not action.

I/O points is an important indicator of PLC.

Reasonable selection of I/O points can not only satisfy the control requirements of the system,

And the total investment of the system is the lowest.

The input and output pooints and types of PLC should bee determined according to the analog quantity and switch quantity of the controlled object,

Generally an input / output element to take up an input / output point A65P.

Taking into account the future adjustment and expansion,

In general should be estimaateed on the total number of points plus the amount of spare 20%~30% A65P.

The following describes the centralized control system I/O points of the estimate.

A65P Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=A65P&select=5

Input / output (resolution): 0 ~ 4000.

Conversion speed: 100ms/4 channel.

Analog module installation.

Power supply: AC170V ~ 264V.

According to the control requirements of the system, using the appropriate design method to design MITSUBISHI PLC program.

Procedures to meet the requirements of system control as the main line,

Write one by one to achieve the control function or the sub task of the program,

Gradually improve the functions specified by the system A65P

MITSUBISHI PLC detection, fault diagnosis and display and other procedures.

These procedures are relatively independent, generally in the basic completion of the program design and then add A65P.

Hardware simulation method is to use a number of hardware equipment to simulate the generation of the signal,

The signals are connected to the input end of the PLC system in a hard wired way, and the timeliness is strong .

Software simulation method is in the MITSUBISHI PLC in the preparation of a set of simulation program,

The simulation provides the field signal, which is simple and easy to operate, but it is not easy to guarantee the timeliness A65P.

Simulation of the process of debugging, debugging method can be used to segment, and the monitoring function of programmer. Input voltage range: AC100 ~ 120V.

Output voltage: DC24V.

Output current: 0.6A.

Relay output interface circuit of PLC

Working process: when the internal circuit output digital signal 1,

There is a current flowing through, the relay coil has a current, and then the normally open contact is closed,

Provide load current and voltage.

When the internal circuit outputs a digital signal 0, there is no current flowing through it,

The relay coil does not have a current, and the normally open contact is broken off,

A current or voltage that is disconnected from the load.

It is through the output interface circuit to the internal digital circuit into a signal to make the load action or not action.

I/O points is an important indicator of PLC.

Reasonable selection of I/O points can not only satisfy the control requirements of the system,

And the total investment of the system is the lowest.

The input and output pooints and types of PLC should bee determined according to the analog quantity and switch quantity of the controlled object,

Generally an input / output element to take up an input / output point A65P.

Taking into account the future adjustment and expansion,

In general should be estimaateed on the total number of points plus the amount of spare 20%~30% A65P.

The following describes the centralized control system I/O points of the estimate.

A65P Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=A65P&select=5

...more relevant model market price >>>>

Related products

MITSUBISHI

Temperature input module

A616TD

16 channels.

A616td and a68rd3/4 thermoc

MITSUBISHI

AD conversion module

A616AD

16 channels.

Input: DC-10 10V, DC-20

MITSUBISHI

Quick connector plug

A6CON-P214

A pack of 20.

Applicale models:

AJ65SBT

MITSUBISHI

Enclosure

A6ADP-2MC16D

34 point with the wiring transformation