A1SCPU

- Brand: MITSUBISHI

- Country: JAPAN

- Name: CPU unit

- Model: A1SCPU

- Price: U.S.$ 1310.17

MITSUBISHI A1SCPU

Motor series: medium inertia, medium power.

Rated output power: 3.5kw.

Rated speed: 2000r/min.

Whether to bring the brakes: with.

Shaft end: Standard (straight).

Power supply: 400V type.

Protection level: IP65 (IP67).

Features: medium inertia from low speed to high speed three modes for selection, suitable for different applications .

Application examples: transmission machinery, robots, X-Y working platform A1SCPU

High resolution encoder 131072p/rev (17 bit).

The encoder with high resolution ensures excellent performance and stability at low speed.

All motor dimensions are the same as before and all are compatible with the wiring. Motor series: low inertia, medium capacity A1SCPU.

Rated output power: 12 . 0kw.

Rated speed: 1000rpm.

With the brake: without.

Shaft end: straight shaft.

The rotor of the servo motor is a permanent magnet, which is controlled by the U/V/W,

The rotor rotates under the action of the magnetic field, and the encoder feedback signal of the motor is given to the driver,

According to the feedback value and the target value, the driver adjusts the rotation angle of the rotor A1SCPU.

Accuracy of the servo motor depends on the accuracy of the encoder (number of lines). Type: HF-KN servo motor, low inertia, low power.

Rated output power: 0.4kw.

Rated speed: 3000r/min.

Electromagnetic brake: there.

Oil seal: have.

Encoder resolution: 131072p/r.

S100 representative: Super MR-E special motor.

KH003 special mark for Super MR-E.

High performance and easy to operate, reduce work load.

Enhanced system cost performance.

High performance, high precision positioning (servo motor encoder resolution: 131072).

High response.

Suppression of vibration by adaptive vibration suppression control.

Using personal computer and servo setup software to optimize tuning.

Has 2 types of interfaces:

Position control and speed control with pulse train interface.

The analog input interface is used for speed control and torque control.

Wide use.

Macchining equipment and machine tool feed A1SCPU.

Used for food, packaging equipment and feeding device.

For textile machinery, etc..

Can improve the performance of equipment.

Servo amplifier terminals are used to reduce the required wiring time.

The connector is located in front of thhe servo amplifier, which is convenient for cable connection A1SCPU.

The gain adjustment can be easily carried out by the real-time automatic tuning function.

A1SCPU Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=A1SCPU&select=5

Rated output power: 3.5kw.

Rated speed: 2000r/min.

Whether to bring the brakes: with.

Shaft end: Standard (straight).

Power supply: 400V type.

Protection level: IP65 (IP67).

Features: medium inertia from low speed to high speed three modes for selection, suitable for different applications .

Application examples: transmission machinery, robots, X-Y working platform A1SCPU

High resolution encoder 131072p/rev (17 bit).

The encoder with high resolution ensures excellent performance and stability at low speed.

All motor dimensions are the same as before and all are compatible with the wiring. Motor series: low inertia, medium capacity A1SCPU.

Rated output power: 12 . 0kw.

Rated speed: 1000rpm.

With the brake: without.

Shaft end: straight shaft.

The rotor of the servo motor is a permanent magnet, which is controlled by the U/V/W,

The rotor rotates under the action of the magnetic field, and the encoder feedback signal of the motor is given to the driver,

According to the feedback value and the target value, the driver adjusts the rotation angle of the rotor A1SCPU.

Accuracy of the servo motor depends on the accuracy of the encoder (number of lines). Type: HF-KN servo motor, low inertia, low power.

Rated output power: 0.4kw.

Rated speed: 3000r/min.

Electromagnetic brake: there.

Oil seal: have.

Encoder resolution: 131072p/r.

S100 representative: Super MR-E special motor.

KH003 special mark for Super MR-E.

High performance and easy to operate, reduce work load.

Enhanced system cost performance.

High performance, high precision positioning (servo motor encoder resolution: 131072).

High response.

Suppression of vibration by adaptive vibration suppression control.

Using personal computer and servo setup software to optimize tuning.

Has 2 types of interfaces:

Position control and speed control with pulse train interface.

The analog input interface is used for speed control and torque control.

Wide use.

Macchining equipment and machine tool feed A1SCPU.

Used for food, packaging equipment and feeding device.

For textile machinery, etc..

Can improve the performance of equipment.

Servo amplifier terminals are used to reduce the required wiring time.

The connector is located in front of thhe servo amplifier, which is convenient for cable connection A1SCPU.

The gain adjustment can be easily carried out by the real-time automatic tuning function.

A1SCPU Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=A1SCPU&select=5

...more relevant model market price >>>>

Related products

MITSUBISHI

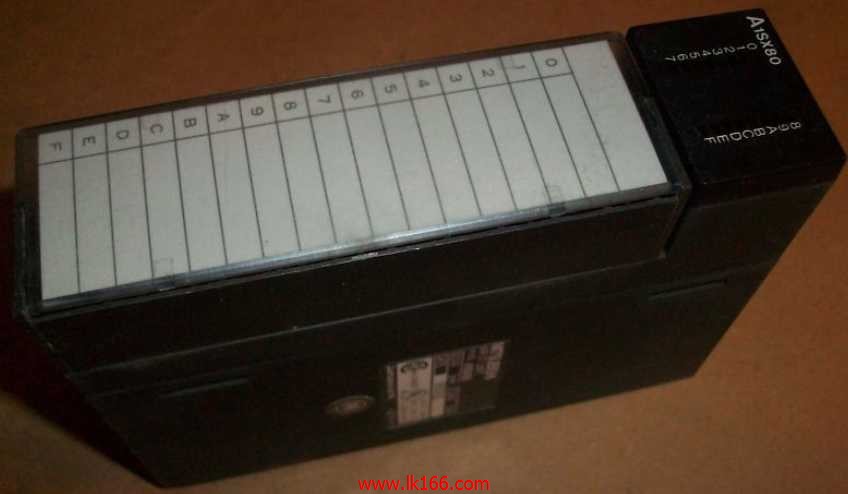

DC source type input module

A1SX80

Type of input: DC source.

Input points:

MITSUBISHI

Input / output module

A1SH42P

Enter 32 points.

2/5mA DC12/24V.

Respons

MITSUBISHI

32: terminal line adapter

A1S-TA32-7

32: terminal line adapter 0.75mm2 AGW18

MITSUBISHI

General purpose CPU

Q20UDHCPU

Specification model: Q20UDHCPU.

Input /