Input: 4 channels.

Platinum resistance (Pt100; JPt100).

Heater disconnection detection function.

Sampling period: 0.5s/4 channel.

18 point terminal table x2.

Can be flexible in various settings, to achieve the best temperature control of the temperature control module.

Equipment for high temperature control stability of extrusion molding machine,

Thee temperature regulating module has the function of preventing overheating and preventing over cooling QA68B.

According to the control object device, select the standard control (heating or cooling) or the heating and cooling control (heating and cooling) mode QA68B.

In addition, the mixed control mode (combined with the standard control and heating - cooling control) can be selected.

Peak current suppression.

Can prevent the simultaneous opening of the output to control the peak current, which is helpful for saving energy and reducing the operation cost QA68B.

Heating function at the same time.

The multiple loop can reach the set value at the same time to carry out the uniform temperature control,

Helps to prevent no-load and effective energy saving and reduce operating costs MITSUBISHI QA68B.

Automatic adjustment function.

The PID constant can be adjusted automatically in the control process.

Automatic adjustment of cost (time, material and electrical energy) can be reduced. Control axis: up to 16 axes.

Interpolation function: linear interpolation (maximum 4 axis), arc interpolation (2 axis), spiral interpolation (3 axis) MITSUBISHI QA68B.

PLC capacity: 30K step.

Small scale systems with high performance to price ratio.

Power supply, programmable sensor, motion controller trinity.

Maximum control axis: 16 axis MITSUBISHI QA68B.

Support visual system.

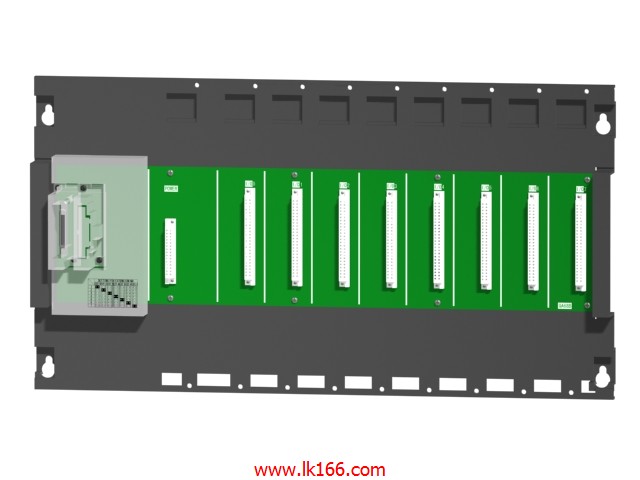

8 slots.

Requires 1 power modules.

Used to install the old section of the large A series PLC module.

Switch volume control is designed to,

According to the current input combination of the switch quantity and the history of the input sequence,

So that PLC generates the corresponding switching output,

In order to make the system work in a certain order.

So, sometimes also known as the order control.

And sequential control is divided into manual, semi-automatic or automatic.

And the control principle is decentralized, centralized and hybrid control three.

Each scanning process. Focus on the input signal sampling. Focus on the output signal to refresh.

Input refresh process. When the input port is closed,

Program in the implementation phase, the input end of a new state, the new state can not be read.

Only when the program is scanned, the new state is read.

A scan cycle is divided into the input sample, the program execution, the output refresh.

The contents of the component image register are changed with the change of the execution of the program.

The length of the scan cycle is determined by the three.

CPU the speed of executing instructions.

Time of instruction.

Instruction count.

Due to the adoption of centralized sampling.

Centralized output mode.

There exist input / output hysteresis phenomena, i.e., the input / output response delay.

System program memory for storing system proogram,

Including management procedures, monitoring procedures, as well as the user program to do the compiler to compile the process of interpretation QA68B.

Read only memory. Manufacturers use, content can not be changed, power does not disappear.